Myth 1

The digital transformation of infrastructure requires the replacement of all existing instruments with new devices that integrate IoT communications.

Instrumentation does not need to be updated to adapt to IoT technology. There is also no need for further investment to replace the existing devices. To connect our infrastructure, we simply have to add a gateway to bring the data generated by the existing instruments to the management platforms in a secure, fast and interoperable way.

Large infrastructure deals with a legacy of many years of investment in both their OPEX and CAPEX, with payback periods that are looked at closely. Infrastructure must be adapted to the new connectivity requirements. Digital transformation is achieved by adding a new technological layer enabling data to be transmitted in a standardised way. Furthermore, this task must be achieved regardless of whether the existing asset communication protocols are five, ten or twenty years old.

Myth 2

My current instrumentation partners and manufacturers will have to provide me new products ready to be connected through NB-IoT with my middleware and cloud platforms.

Experts in sensors and metering technology are not necessarily also experts in electronics, telecommunications, cloud platforms and all the aspects that are necessary for the digital transformation of existing assets in infrastructures.

In the pre-digital era there were two fundamental areas in any industry: operations (logistics and manufacturing of goods) and commercialisation (marketing and sales). In the new digital age, a new axis has formed that changes and connects these two worlds. The measuring technology that is used today connects the site where the measurement is taken with the customer via the internet.

The connection between technology and end users helps us to anticipate customer needs, make quick and well-informed decisions and optimise every service. Nowadays, it seems natural for us to outsource processes within the production chain. Thus, suppliers help to optimise quality, time and costs whereas in the commercial sector marketing agencies, call centres or distribution networks come into play.

In the digital transformation of infrastructures, we are dealing with a similar scenario. Both in resource management (water or energy) and among instrumentation manufacturers, the knowledge required to pave the path towards digitisation is limited. Thus, companies continue to rely on external partners to further develop the digitisation of infrastructure and tools. Datakorum enables interoperability within the new digital IoT-ecosystem.

Myth 3

Digital transformation starts when I’m able to implement intelligence decision making in my organisation.

The digitisation of infrastructure begins with the collection of data at the physical location on site. Infrastructure 4.0 has tried to put the cart before the horse. In BTC it was the users who proactively generated all these interactions, which were then converted into data with the help of digital technologies. Within the “IoT” concept, things have to be “smart”, meaning that things have to be able to generate data as if they were a user.

Things themselves are not capable of generating information in an understandable and structured way, let alone transmitting it in such a way that it can be intelligently analysed for decision-making. Within Industry 4.0, there are already numerous concepts such as mathematical models, digital twins or even “edge computing”.

If we want to successfully implement all these concepts, we have to keep in view the technological as well as the telecommunications processes necessary to generate secure, reliable, stable and sustainable communication. We must build a strong foundation by digitising our infrastructure, if we do not want to be constrained in the future.

Myth 4

The digital transformation of infrastructures will be agnostic regardless of the communications system. Anything goes.

It is NOT true that any communications system transmitting data is valid, quite the opposite. It is crucial to choose the specifications we need to meet to ensure stable and secure communication. Within a controlled environment such as a factory or building, WiFi, LoRa or even in-house systems may be used.

It is completely different when we deal with a mains flow meter that may be located in a pit more than five metres underground in a remote location. Many communications protocols are vulnerable and while they may be suitable for communications between users or within a local area network (LAN), they are not suitable for the basic services of a city or industrial infrastructure.

NB-IoT and LTE-M technologies are part of the 3GPP standard for 5G networks. They have been chosen as the most robust and reliable technology for infrastructure deployment and will certainly be the standard in IoT infrastructure communication. Already now, a number of countries have already deployed these networks for massive IoT (mIoT) deployments.

Communications systems for basic infrastructures can neither be proprietary nor free or open access as they are not secure and they do not offer 24/7 service levels at all times and in every location.

Telecommunications providers are the experts and they are best suited to guarantee the status and security of communications. This responsibility cannot be transferred to others; the economies of scale allow sustainable costs and a continuous updating of technology in order to meet future needs.

Myth 5

The digital transformation of infrastructures will be hardware agnostic.

The chain always breaks at the weakest link. Devices that perform the digitisation of your data poorly or insecurely can lead to vulnerabilities in the entire infrastructure value chain.

Cybersecurity is one of the most critical issues within the digital transformation of infrastructures. This chain starts with the hardware, passing through the firmware, software, the telecommunications network, middleware, and the final platform. Each link has to pass the highest levels of security in the creation, encryption, authentication and transmission of data.

Cybersecurity of a country’s strategic assets must be a priority for the entire ecosystem. The incident of the cyber-attack on the Colonial pipeline in the United States has cost billions and, above all, has shown that Industry 4.0 cyber security is crucial.

Myth 6

Digital transformation requires a management system that is able to carry out data analyses and make the right decisions based on them.

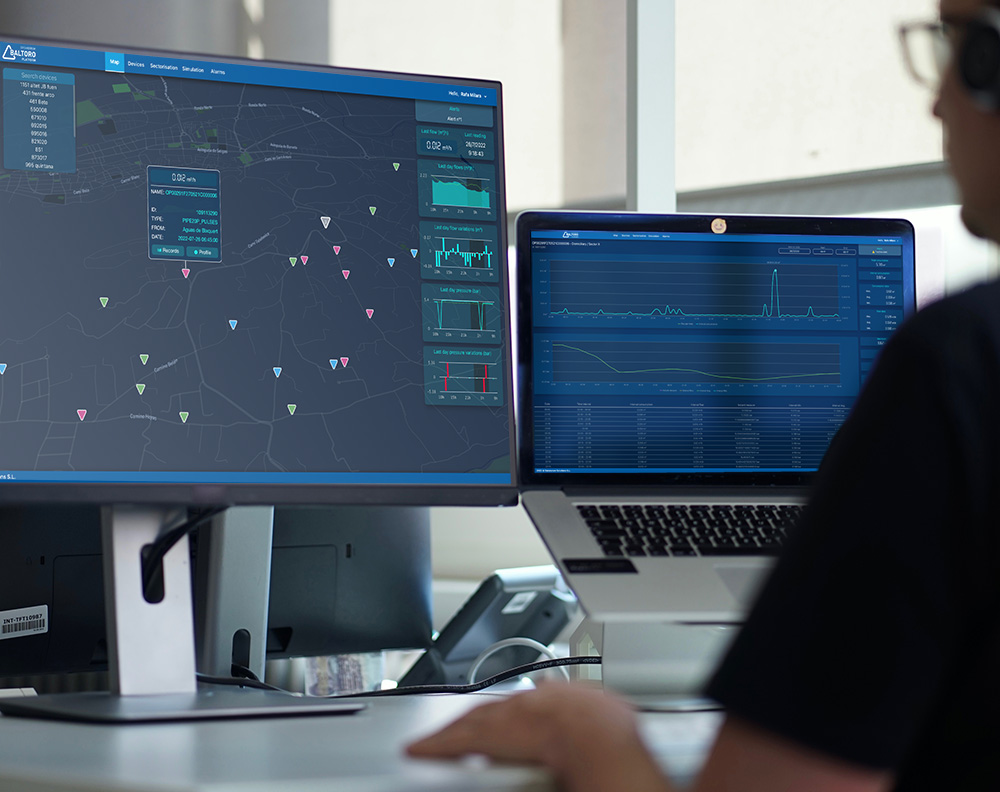

The data management system in the cloud is the first phase of digitisation, but the data path must be bidirectional. Furthermore, we have to take into account that decisions will be made on the platform and partly distributed among all devices (Edge Computing).

The most important thing within digital development is interactivity, which means that bidirectional relationships are learning to become smarter and smarter. The same applies to things. Communication systems require that hardware, firmware, software, middleware as well as the final platform have the ability to handle the data bidirectionally.

For things to be able to make decisions, they have to be made intelligent, they have to be trained. Thus, they need to be able not only to send and receive data, but also to execute actions.

This brings us back to the distinction between Internet 2.0 and 4.0. Things need a brain, a communications system as well as the ability to carry out commands. It is about managing the flow of data throughout the chain, back and forth through hardware, firmware, software, middleware and the cloud. There is no edge computing without a solution for data flow and interoperability with all existing tools in the infrastructure.

We have learned from Internet 2.0 that the best analysis is the one that is done with improvement. At best we have data visualisation dashboards and daily reports that end up not being analysed – or if they are, the fact of not making decisions in time created costs. Industry 4.0 is a gift, because closing or opening a valve or water pump is now an automatic process, without any need for manual intervention.

Myth 7

The digital transformation of infrastructures will be gradual and the process will take years. We don’t need to be the first… take you time.

Nothing could be further from the truth, because the digital transformation has already begun and will take place in the next 5 years. Within the digital transformation, the pace is not set by the companies in the sector, i.e., the utilities or equipment manufacturers, because they resist change and the unknown. Instead, the pace is usually set by technology outsiders without any legacy systems and processes.

The impact of digitisation is similar across all industries and has a graph indicating exponential growth in the form of a Hockey Stick. If we look at the development on a graph, we see a period in which virtually nothing changes, but suddenly the curve rises inexorably vertically.

Look at the growth of Amazon, SalesForce or Shopify over the last ten years. We see exactly the same development in Industry 4.0: The effects are not yet visible, but those who do not act now will regret it later. In the water sector, Australia, the United Arab Emirates and Singapore have already given top priority to the digital transformation of their infrastructures. There is still time to react – but we should take our chance now.